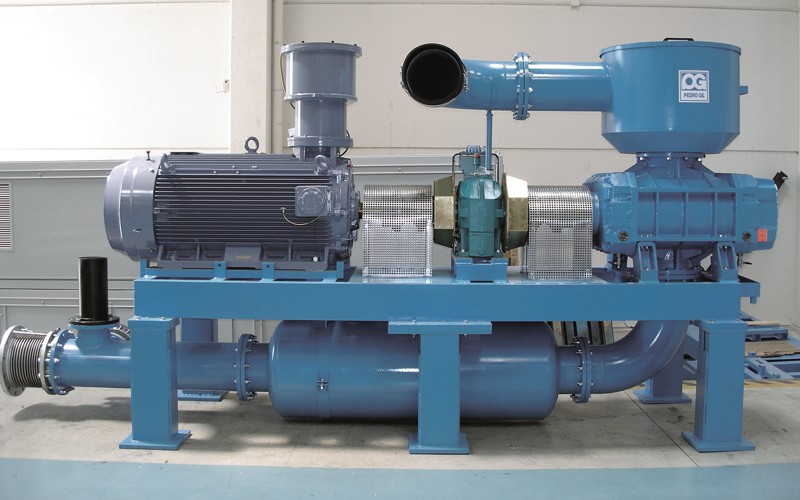

Rotary blower

Rotary piston compressors for pressure and vacuum

In this overview you can see our standard Positive Displacement Blowers for pressure and vacuum. Of course you can also order frequency controlled systems, ATEX versions, special coatings, various accessories etc.. Operating instructions are available in the languages D, EN, ES, other languages on request. Step files, CAD files can be sent to you on request.

Our advantages:

- Competent advice

- Long-lasting, reliable industrial quality

- Continuous use suitable

- We also supply for special applications

- Special versions

- Special coatings

- ATEX versions

Your contact person

Christian Dünnwald

Fon: +49 2151 9931 61Standard equipment:

- Low pulsation three-bladed rotary piston

- Silencer filters for pre-inlet cooling

- Protective filter with adapter for the safety valve

- check valve

- Safety valve Type A

- Silencer at the air or gas outlet

- axial expansion joint

- Vibration damper with anchor bolts

- V-belt drive

- V-belt protection for the drive

- mounted on support frame

Options:

- Sonic hood with vacuum gauge

- Vacuum controller

- Thermometer

- Service contract (oil change, filter cleaning, V-belt tension, bearing check)

- Instruction for initial start-up

- Startup relief valve

- Compensator made of stainless steel (Recommended for pressures above 700 mbar)

- Pressure and vacuum gauges, thermostats, ...

- Spare part offer for 2-5 year operation

If you do not find the required volume flow or the suitable size, please contact us. We will help you to find the best blower for your energy requirements. .

Rotary piston compressors, also known as rotary blowers, roots compressors or roots blowers, are robust endurance runners. They convey and compress air or gases in a continuous air or gas flow. Positive displacement blowers are assigned to the group of valveless positive displacement compressors without internal compression.

Rotary piston blowers are used to generate both positive pressure and negative pressure or vacuum. Rico Positive Displacement Blowers have high availability, energy efficiency and freedom from oil in robust industrial applications and are durable, economical and powerful.

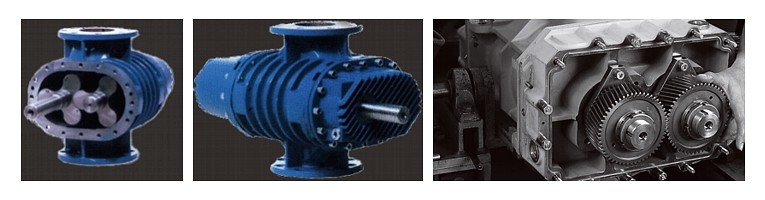

Two identical, normally symmetrical, counter-rotating rotors operate in one housing and are synchronized with a series of gears.

The use in the field of extraction, cooling, ventilation or pneumatic material transport is extremely versatile. The economical, low-maintenance rotary lobe blower can be described as a "reliable and robust continuous runner" that transports air and almost all technical gases. The blowers are usually air-cooled and oil-free.

Features of our Positive Displacement Blowers

- Our Positive Displacement Blowers are designed for long running times in continuous operation with high reliability.

- The pressure increase for air and neutral gases is up to 1000 mbar or 800 mbar [200 mbar abs] negative pressure, for volume flows from 19 to 9180 m³/h. Compression is oil-free and low-pulsation.

- The 3-winged rotors with their shafts are forged from one piece in a die. They also help to reduce the pulsation frequency and the sound level.

- Large ribs on the housing ensure good heat dissipation. The materials used for the GP 30 & GP 35/38 Positive Displacement Blowers are remarkable: Housing, side plates and cover are made of GG20 cast iron. The rotors of the blower types up to GP 35/38 are made of CK45 with a tensile strength of 700 N/mm2. The helical synchronisation wheels made of high-strength case-hardened steel 18CrMo4 are hardened and ground.

- The housings have a pressure shock resistance of 13 bar.

- The blowers are dynamically balanced and tested and documented at the individual assembly stations.

- The selection of bearings is particularly important for longevity and reliability.

- High-quality brand bearings are used depending on the fan size, load and speed. Basis for the determination of the bearings is the design for 60000 operating hours running time, at normal load according to ISO 281. .

- Fans are driven by electric motor and V-belt drive with automatic belt tension.

- The blowers are mounted on elastic elements, a foundation is not required.

- The on-site commissioning of the blower unit comprises installation, pipe connection, oil filling and electrical connection.

- Acoustic enclosures for indoor and outdoor installation are available as accessories.

- The sound enclosures are segmented, lined with insulating material on the inside and powder-coated in RAL 7044/7039 on the outside.

- Each acoustic enclosure is equipped with an electric fan; the instruments can be read from the outside.